Article | July 8th, 2018

Banyard Billet Heaters – 50 Years Strong, Forefront of Innovation

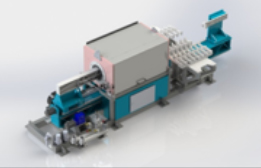

Over 50 years ago, Banyard developed an induction system used in the process of aluminum extrusion. As the industries that utilise extruded aluminum have developed and expanded, the Banyard technologies have evolved along with them. The strong foundation of the Banyard brand has allowed for the core technology to have longevity in the marketplace whilst the research and development efforts continue to keep Banyard at the forefront of innovation. As such, Banyard has long been the brand trusted by aluminum extruders around the world.

The Advantages of Banyard Induction Technology Post-Heating

Unlike traditional gas furnaces that heat metals from the outside in, induction technology consists of coils which create an electromagnetic current that couples with the metal to efficiently heat it from within. Implementation of the Banyard induction technology in line with traditional gas heating systems provide considerable advantages to aluminum extruders, most notably a very precise temperature heating profile.

Banyard induction technology takes induction heating to the next level for aluminum extrusion. With several heating zones, the individual coils can be at different temperatures across the billet which allows the material to be heated at a gradient and offers even greater flexibility and increased precision in the heating and extruding process. These induction heaters provide a substantial improvement in the quality of finished product due to this optimized temperature control capability. A hybrid approach is often implemented which involves pre-heating the aluminum with gas and then transferring it to the induction furnace for the final heating process. This provides a production option that is both economical, efficient and precise.

The Banyard Difference

Whilst Banyard’s core technology has fundamentally remained the same through the years, its digital IGBT power conversion technology and user interface are state-of-the-art and deliver increased reliability, greater accuracy and reduced maintenance for aluminum extruders. An investment in Banyard technology is one that you can depend on for many years to come.