Article | December 19th, 2019

Dr. Valery Rudnev: Induction Thoughts

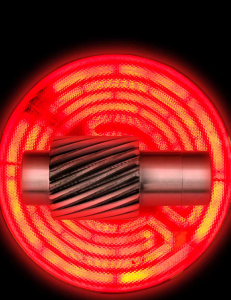

Induction heating of steel billets: causes of billet sticking/fusing problem and its prevention

Steel components by far represent the majority of hot-worked billets and bars for which electromagnetic induction is used as a source of heat generation. At the same time, Ni-base superalloys, Ti, Cu, Mg, Al as well as many other non-ferrous metals and alloys are also inductively heated for a number of commercial applications producing various shapes, properties and microstructures.

Temperature greatly affects the formability of metals. Heating of a workpiece through its cross-section to temperatures of the plastic deformation range creates a favorable condition for metal to be subsequently forced by various means into a wanted shape. The versatility of induction heating (IH) is associated with its ability to heat the workpiece entirely or its specific areas uniformly or, if preferred, creating appropriate thermal profiles.

The most popular metal hot working processes for which IH is applied are as follows:

Forging : Billets, rods, bars, and the like are heated either in cut lengths or continuously, and are forged in presses, hammers, upsetters, etc.

Forming : Hot forming includes a variety of metal-working operations generally encompassing bending, expanding, spinning, and some others.

Extrusion : This process relies on forcing or squeezing heated materials through a die, as it takes place in direct and indirect extrusion.

Rolling : Bars, rods, rings, plates, etc. are rolled into the desired sizes and shapes.

Click here to view/download the full article.