Industries

Aerospace

The size and growth of the aerospace market—both within the US and throughout the world—is difficult to define and calculate. It is comprised of two major sectors: Aerospace (commercial aircraft of all kinds) and Defense. The recessions of 2008-2009 hit the industry hard, resulting in a significant drop in units produced and shipped within the general aviation segment of the market. Offsetting that, the industry has seen a dramatic rise in cost – the average general aviation aircraft today has doubled in price from 2007.

Amidst all this change there are important constants, including the demand for metal components that meet stringent standards for quality, structural integrity, weight, cost and more. While steel and aluminum are still used to some extent, the properties of titanium—including strength, temperature resistance and corrosion resistance—make it perhaps the most-favored metal in aerospace construction.

Related Resources

Select a Process

Boost Induction Heaters

The Banyard Boost Induction Heater has established itself as a low cost, highly compact, induction boost taper heater for use with either gas or induction pre-heaters. Using a servo-controlled billet positioning system to control both accuracy and speed, the Boost Induction Heater enables extruders to boost billet temperature and line speed, with a consequent increasehttps://www.inductothermgroup.com/products/boost-induction-heaters/...

LEARN MORE »

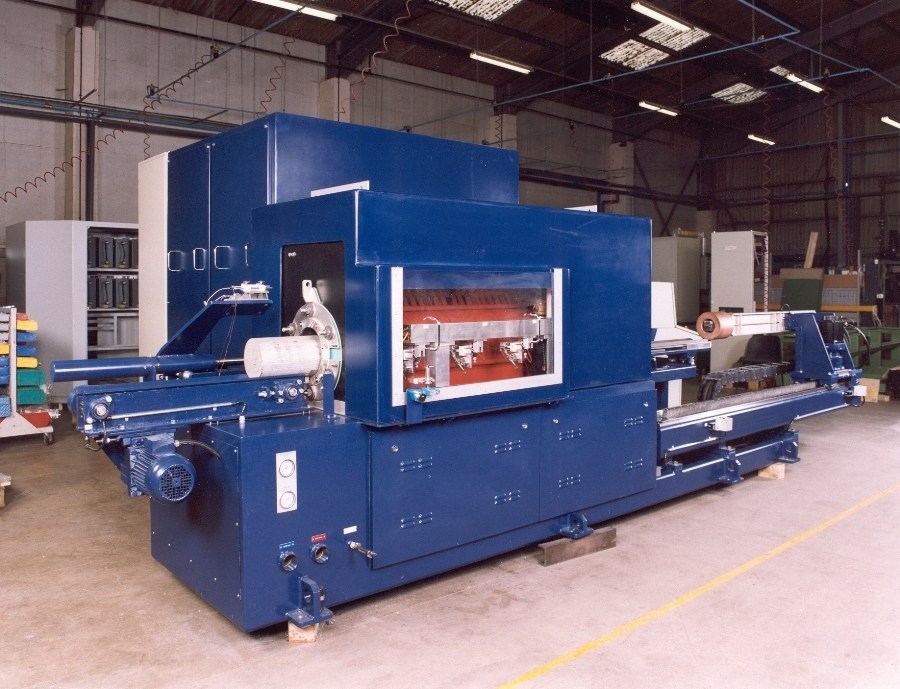

Horizontal Billet Heaters (nonferrous)

Inductotherm Group’s development of phase synchronized multi-zone power modules has made accurate static taper heating possible. A static taper heating coil is divided into a number of independently controlled zones, each with its own thermocouples executing its own power profile. This enables optimum temperature control. Synchronization of the modules ensures that there is a seamlesshttps://www.inductothermgroup.com/products/horizontal-billet-heaters-nonferrous/...

LEARN MORE »

Slab, Bloom and Transfer Bar Heaters

Our high-power density Slab, Bloom and Transfer Bar Heaters provide efficient and cost-effective technologies to bring surfaces to the optimal temperatures required for forming, rolling or forging. Metals which are susceptible to oxidation and scale formation such as titanium, if heated above certain temperatures, can be accurately heated using induction heating, thus increasing yield andhttps://www.inductothermgroup.com/products/slab-bloom-and-transfer-bar-heaters/...

LEARN MORE »

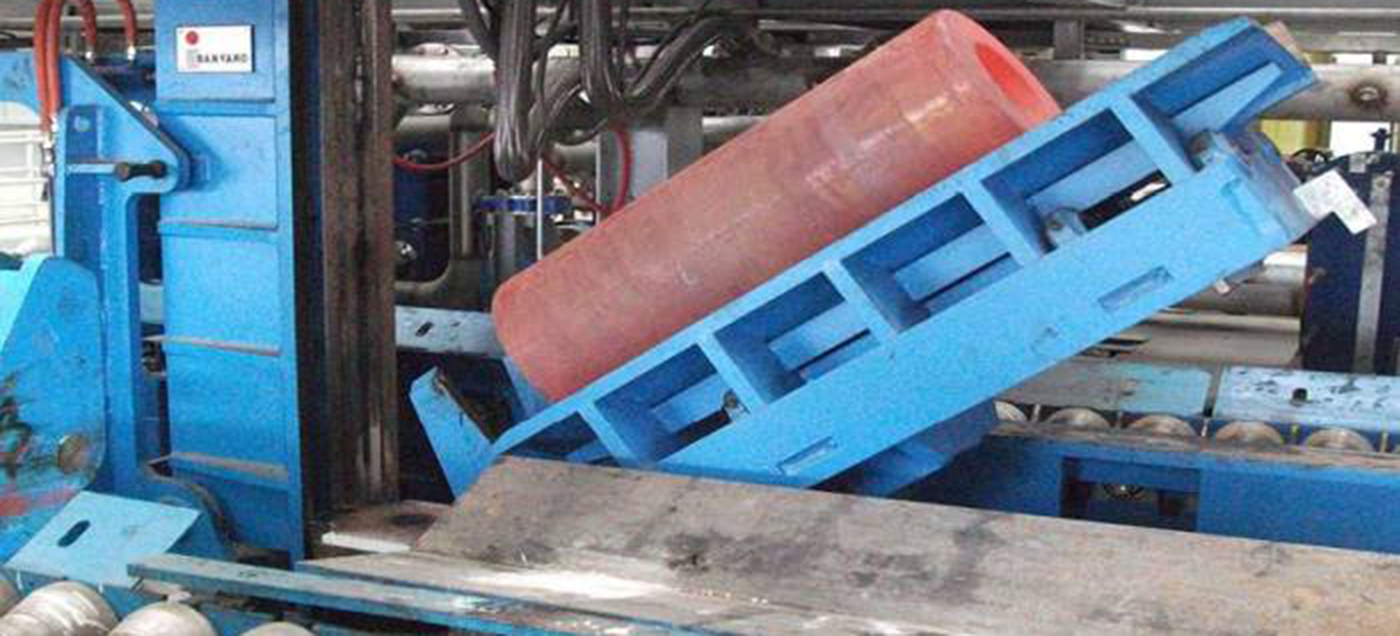

Vertical Billet Heaters

Banyard Vertical Steel Induction (VSI) systems have been designed for the precise vertical induction heating of solid or pierced billets and tubes. These systems heat billet diameters from 150mm to 460mm, and lengths from 300mm to 1500mm. Benefits include better temperature distribution, ability to vary the temperature profile along the billet length, and no billethttps://www.inductothermgroup.com/products/vertical-billet-heaters/...

LEARN MORE »

Zero Friction Billet Heaters

Banyard brand induction heating systems feature special mechanical handling technology designed specifically to address the needs of the aluminium micro-tubing sector. The Banyard solution enables aluminum billet transport with virtually zero friction. This is achieved by effectively minimizing the area of contact with the billet at all stages of the process. Smooth movement is alsohttps://www.inductothermgroup.com/products/zero-friction-billet-heaters/...

LEARN MORE »

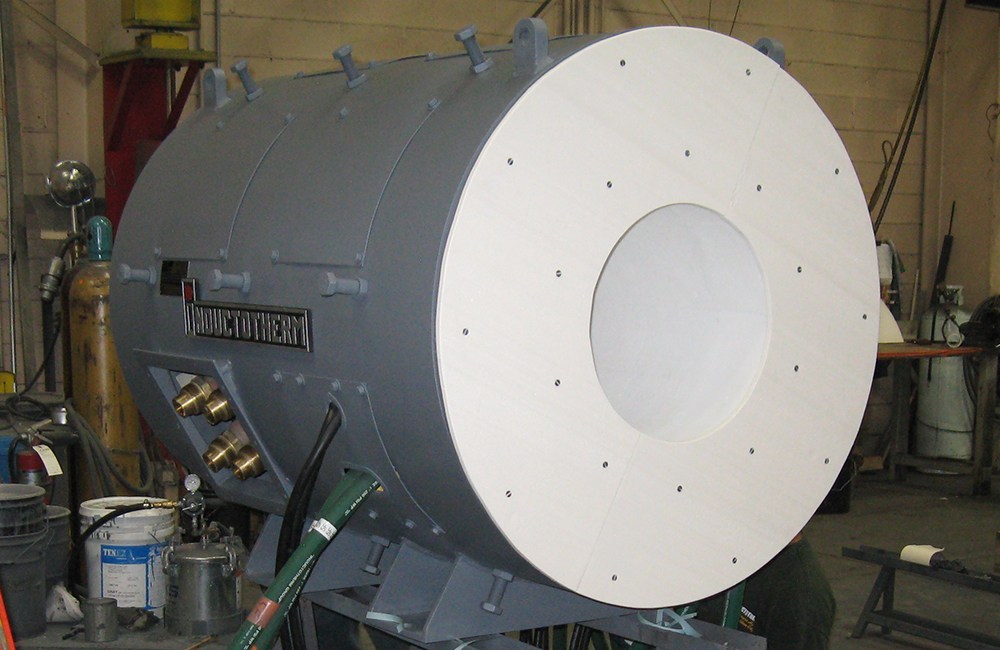

Vacuum Aluminum Brazing Furnaces (VAB)

Vacuum Aluminium Brazing (VAB) is utilized to perform fluxless brazing of aluminum components in a high vacuum environment. The process demands tight control of temperature uniformity together with low vacuum leak rates and high repeatability. VAB will provide a component with very clean, high quality, high strength brazed joints. Consarc offers a wide range ofhttps://www.inductothermgroup.com/products/vacuum-aluminum-brazing-furnaces-vab/...

LEARN MORE »

Vacuum De-oiling Furnaces (VD)

Consarc has developed a range of vacuum thermal de-oiling furnaces to remove oils by volatilization at low pressure and temperature. Unlike aqueous cleaning processes, vacuum de-oiling does not have any requirements for waste water treatment. Also, oil removed from the components can be recycled. For removal of the oil, furnaces are fitted with a speciallyhttps://www.inductothermgroup.com/products/vacuum-de-oiling-furnaces-vd/...

LEARN MORE »

Vacuum Heat Treatment and Brazing Furnaces (VHT)

Vacuum heat treatment is a well-established practice in the aerospace (both OEM and repair), land-based turbine, automotive and tool industries. Controlled thermal processing of components is carried out in a vacuum environment to eliminate the deleterious effects of the charge reacting with the gases present in the air....

LEARN MORE »

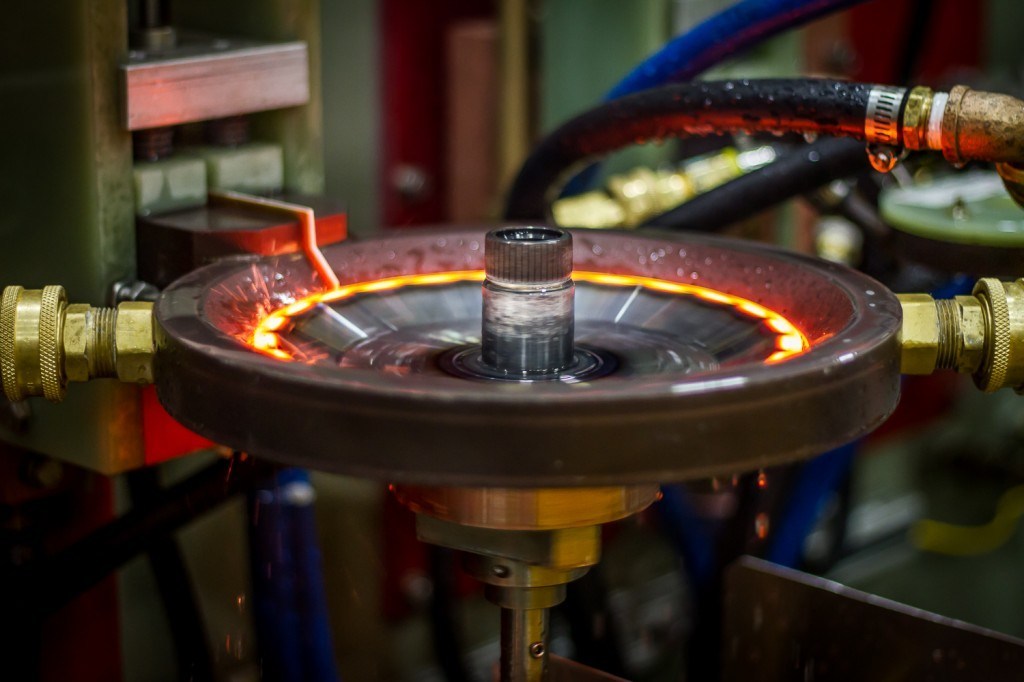

Heat Treat Systems (All Automotive Components)

Many metals require heating and/or heat treating to achieve their optimum physical properties. Inductoheat brand equipment leads the market in quality heating and heat treating with flexible and innovative systems that are designed and built for long-life performance. Inductotherm Group companies’ heat treating equipment gives you the most flexible heat treating solutions, engineered for today’shttps://www.inductothermgroup.com/products/heat-treat-systems-all-automotive-components/...

LEARN MORE »

Induction Scanners

Inductotherm Group companies all over the world manufacture Inductoscan® brand induction scanning systems for scanning, rotary table heating and large part hardening. The modular heating systems’ unique design allows for a wide range of power supplies, controls and components to be integrated within a common base to better match current production needs. It can behttps://www.inductothermgroup.com/products/induction-scanners/...

LEARN MORE »

Induction Melting Furnaces

Inductotherm brand coreless melting furnaces provide superior performance and outstanding durability for all your melt shop needs, regardless of the size of your foundry. Inductotherm Group companies offer a range of furnace sizes from small induction melting furnaces that meet the demanding requirements of investment casters, specialty foundries and the precious metals industry, to heavyhttps://www.inductothermgroup.com/products/induction-melting-furnaces/...

LEARN MORE »

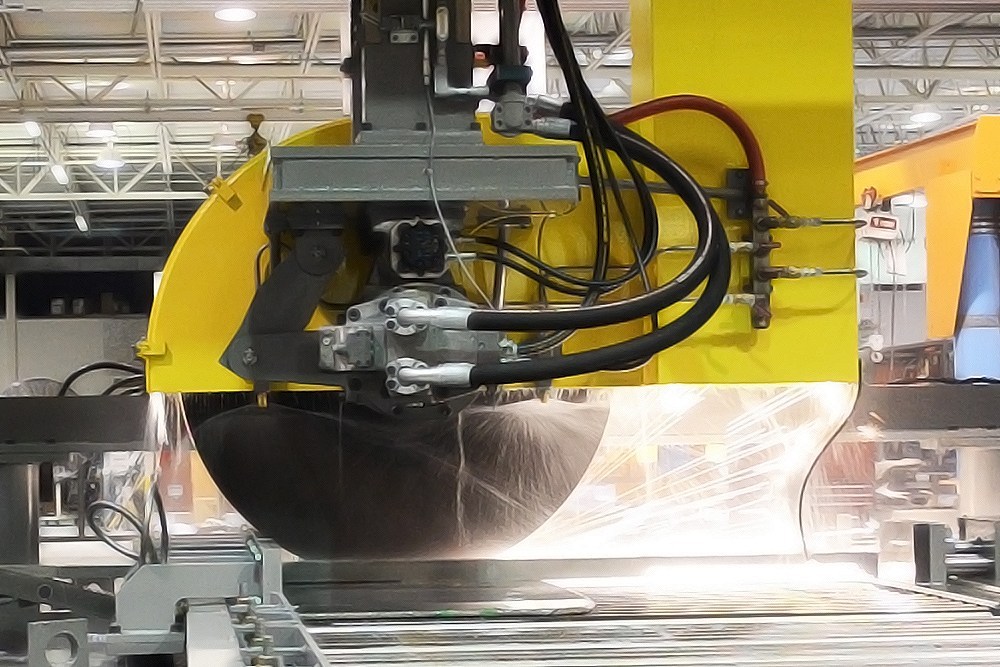

Flying Saws

Inductotherm Group companies offer a range of flying cold and friction saws to meet your tube and pipe cutting requirements. Alpha flying cold saws provide a near burr-free cut. Both single and multiple head designs are available for small or large product, or product which is reshaped into squares or rectangles. Blade surface speed ishttps://www.inductothermgroup.com/products/flying-saws/...

LEARN MORE »

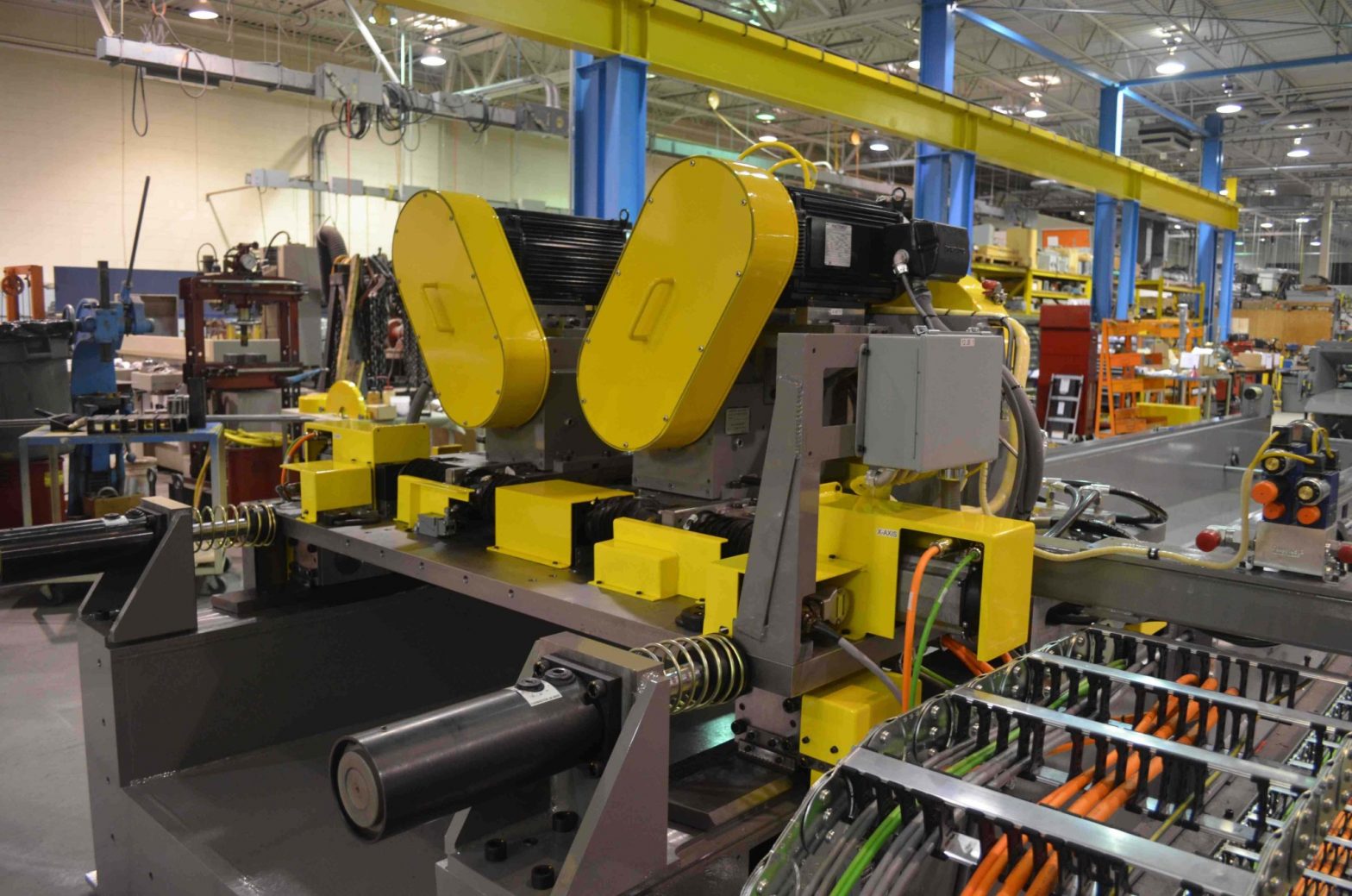

High Frequency (HF) Welders

Thermatool is the world’s leading brand in induction welding equipment. With two decades of success in solid state technology, and over fifty years of process knowledge, Thermatool solid state high frequency welders are the most advanced, reliable, field-proven welders available in the world today. Thermatool solid state welding units are designed to handle load fluctuations,https://www.inductothermgroup.com/products/high-frequency-hf-welders/...

LEARN MORE »

High Speed Flying Shears

Alpha® flying shears are the fastest, most efficient and accurate tube cutting systems available in the world today. Alpha flying shears provide a patented double-cut die set which enables producers to cut dimple-free, ready for market products directly off the mill. Inductotherm Group companies offers a full range of Alpha flying shears for nearly allhttps://www.inductothermgroup.com/products/high-speed-flying-shears/...

LEARN MORE »

Quench and Temper Bar and Tube Equipment

Thermatool™ Quench and Temper lines can process 2, 5, 10, 15, 20 or 30 tons per hour for Austenitizing, Quench and Temper utilizing induction, gas, or electric furnaces coupled with the Thermatool™ Precision Quench™. Thermatool™ Quench and Temper lines feature Solid State Induction power supplies and a patented high-technology modular PrecisionSlot™ Quench. To be effective, these lines require the abilityhttps://www.inductothermgroup.com/products/quench-and-temper-bar-and-tube-equipment/...

LEARN MORE »

Savage Saws™ Brand Saws

Savage Saws™ saws are known for cutting the world’s most high performance, difficult to cut alloys. Servicing the aerospace, automotive, super alloy, and specialty material markets, Savage Saws™ provides precise and repeatable cut quality, in a lean manufacturing capable package....

LEARN MORE »

Strip Heaters

Inductotherm brand equipment brings the world’s most advanced induction heating technology to continuous annealing and coating lines. Equipment includes in-line strip annealing systems, strip heaters, edge heaters, galvanneal heaters, boost heaters, tin reflow systems, paint dryers and anti-fingerprint systems. By adding induction technology to their process lines, customers can significantly reduce yield losses and increasehttps://www.inductothermgroup.com/products/strip-heaters/...

LEARN MORE »

Vacuum Aluminum Brazing Furnaces (VAB)

Vacuum Aluminium Brazing (VAB) is utilized to perform fluxless brazing of aluminum components in a high vacuum environment. The process demands tight control of temperature uniformity together with low vacuum leak rates and high repeatability. VAB will provide a component with very clean, high quality, high strength brazed joints. Consarc offers a wide range ofhttps://www.inductothermgroup.com/products/vacuum-aluminum-brazing-furnaces-vab/...

LEARN MORE »

Vacuum De-oiling Furnaces (VD)

Consarc has developed a range of vacuum thermal de-oiling furnaces to remove oils by volatilization at low pressure and temperature. Unlike aqueous cleaning processes, vacuum de-oiling does not have any requirements for waste water treatment. Also, oil removed from the components can be recycled. For removal of the oil, furnaces are fitted with a speciallyhttps://www.inductothermgroup.com/products/vacuum-de-oiling-furnaces-vd/...

LEARN MORE »

Vacuum Heat Treatment and Brazing Furnaces (VHT)

Vacuum heat treatment is a well-established practice in the aerospace (both OEM and repair), land-based turbine, automotive and tool industries. Controlled thermal processing of components is carried out in a vacuum environment to eliminate the deleterious effects of the charge reacting with the gases present in the air....

LEARN MORE »

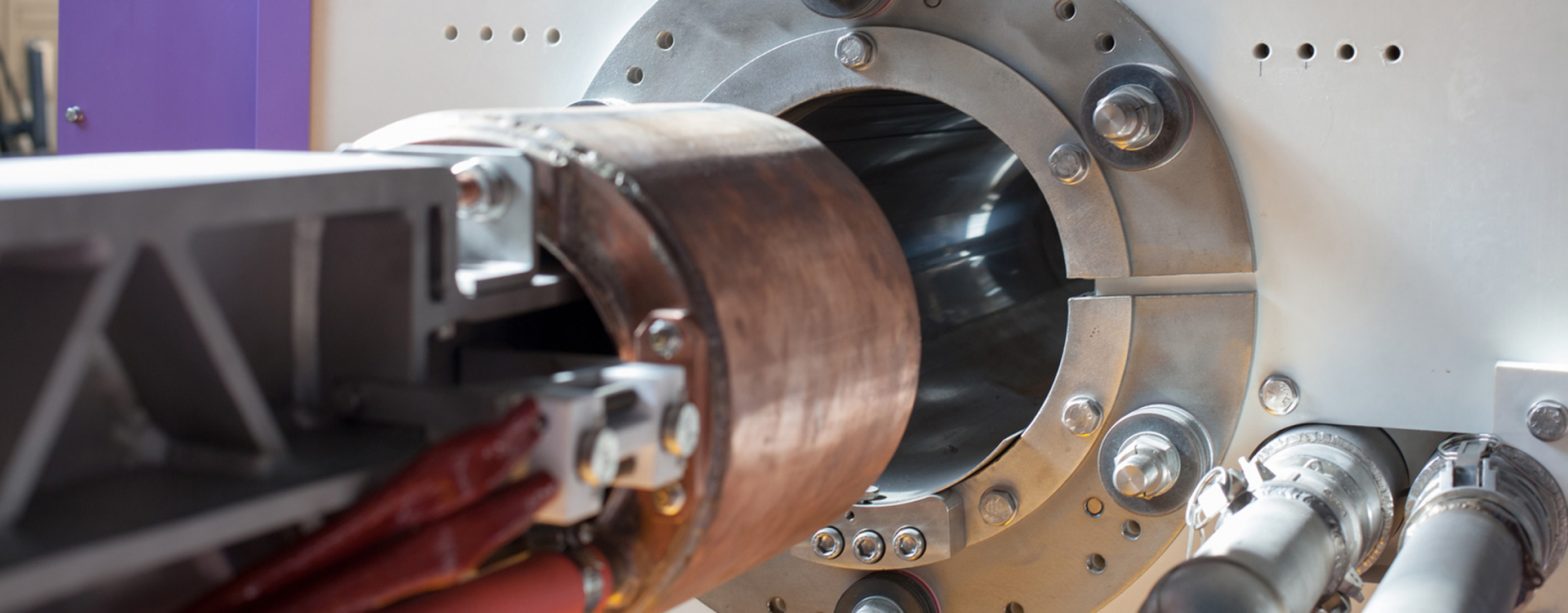

Electromagnetic Cold Crucible (EMCC)

Electromagnetic Cold Crucible (EMCC) is an innovative process utilizing a segmented water-cooled copper crucible for refractory-free induction melting within a vacuum or controlled atmosphere. Melting in a water-cooled copper crucible eliminates the possibility of contamination from the fused silica solar crucible. The copper crucible is made up of water-cooled segments or “fingers.” The magnetic fieldhttps://www.inductothermgroup.com/products/electromagnetic-cold-crucible-emcc/...

LEARN MORE »

ElectroSlag Remelting Furnaces (ESR)

Consarc brand electroslag remelting furnaces improve the efficiency and performance of the process by combining the use of a “high fill ratio” electrode (an electrode whose diameter approaches that of the crucible) with an AC line frequency furnace design in which the main power conductors are arranged coaxially around the melt zone. The high fill ratio electrode provideshttps://www.inductothermgroup.com/products/electroslag-remelting-furnaces-esr/...

LEARN MORE »

Induction Skull Melting Furnaces (ISM)

Consarc offers Induction Skull Melting (ISM) furnaces which is a method of melting metals in a segmented water-cooled copper vessel while under vacuum or controlled atmosphere using an induction coil. Consarc ISM furnaces provide superior chemical and thermal homogeneity when compared to more traditional methods of melting reactive materials such as arc skull casting....

LEARN MORE »

Vacuum Arc Remelting Furnaces (VAR)

VAR Furnaces are used for melting material that have already been melted and cast into electrodes that are near their full packing density. Consarc utilizes fully computerized controls to optimize reproducibility and ease of operation. Custom furnaces in laboratory scale or for the production of unusual geometric configurations are available upon request....

LEARN MORE »

Vacuum Cap Furnaces (VCAP)

The VCAP furnace is designed for Induction Melting a solid charge in an air atmosphere (or vacuum), with final degassing stage under vacuum. The final pouring of the metal is performed in air or under protective atmosphere of inert gas. Configuration is based on the Inductotherm brand of steel shell induction furnaces which are fully adaptedhttps://www.inductothermgroup.com/products/vacuum-cap-furnaces-vcap/...

LEARN MORE »

Vacuum Induction Melting Furnaces (VIM)

Consarc brand equipment includes a variety of Vacuum Induction Melting (VIM) furnaces, including Electrode VIM systems, Master Alloy VIM systems, and small R&D systems. A wide variety of configurations are available to match customer requirements....

LEARN MORE »

Vacuum Precision Investment Casting (VPIC)

Consarc’s line of Vacuum Precision Investment Casting (VPIC) furnaces are uniquely designed to assure repeatable production with minimal maintenance and high furnace availability. Parts with an Equiax grain structure are easily produced in a Consarc VPIC system. With the addition of a mold heater and water-cooled chill plate, directionally solidified and single-crystal castings can behttps://www.inductothermgroup.com/products/vacuum-precision-investment-casting-vpic/...

LEARN MORE »