Processes

Heating and Heat Treating

Metals get their inner strength from heating and heat treating. In most cases, the process involves pushing the temperature of the metal to critical levels, followed by various techniques for soaking and cooling. The end result is a metal that is superior to its original state. Its microstructure may have been changed, mechanical properties may have been enhanced. It is stronger, harder, more stable.

Across multiple Inductotherm Group companies, designers and engineers are working continuously to push the state of the art in heat treating equipment. With a complete line of scanners, single shots and popups handling small and large parts, Inductotherm Group companies can increase part durability and performance by precisely controlling hardening patterns throughout the part. Equally important, our induction systems offer the ability to heat treat in a clean, safe environment with unmatched productivity.

Related Resources

Heating and Heat Treating

Camshaft Hardeners

CamPro™ Induction Heating Systems for camshafts utilize patented SHarP-C™ (Stationary Hardening Process for Camshafts) hardening technology, which eliminates work piece rotation during the induction heat treating process. There are several practical, economical and technical benefits associated with this unique technology including; dramatically reduced maintenance cost, simple operation, longer tooling life, improved part quality and the potential elimination of post heat treathttps://www.inductothermgroup.com/products/camshaft-hardeners/...

LEARN MORE »

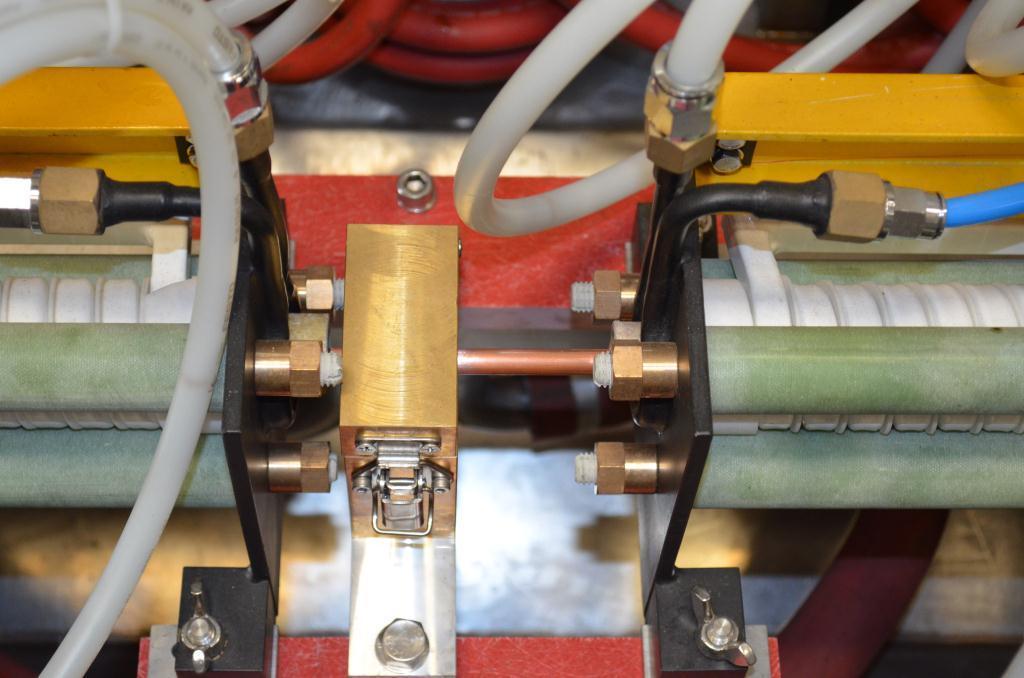

Copper Tube Annealers

Inductotherm Group companies manufacture copper tube annealing systems that reheat copper at high speeds for redraw or annealing. Inductotherm Group companies’ copper annealing systems are complete systems with full line mechanics and feature solid state inverters operating in both medium and high frequencies. Our copper tube annealers also include an electrical control system that featureshttps://www.inductothermgroup.com/products/copper-tube-annealers/...

LEARN MORE »

Crankshaft Hardeners

CrankPro® Induction Heating Systems for crankshafts utilize patented SHarP-C™ (Stationary Hardening Process for Camshafts) hardening technology, which eliminates work piece rotation during the induction heat treating process. There are several practical, economical and technical benefits associated with this unique technology including; dramatically reduced maintenance cost, simple operation, longer tooling life, improved part quality and the potential elimination of post heat treathttps://www.inductothermgroup.com/products/crankshaft-hardeners/...

LEARN MORE »

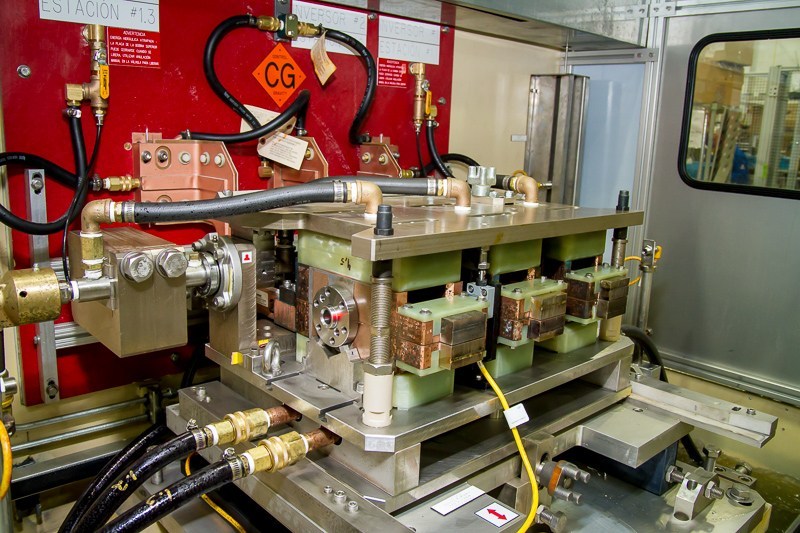

General Heat Treat Systems

Radyne brand heat treatment systems offer flexible, robust induction heat treating that can be effortlessly integrated into your production ecosystem. Radyne heat treat systems include a full line of scanners and pop-ups to handle large and small parts, from parts under an ounce and shorter than an inch to parts over 5000 lbs. in weighthttps://www.inductothermgroup.com/products/general-heat-treat-systems/...

LEARN MORE »

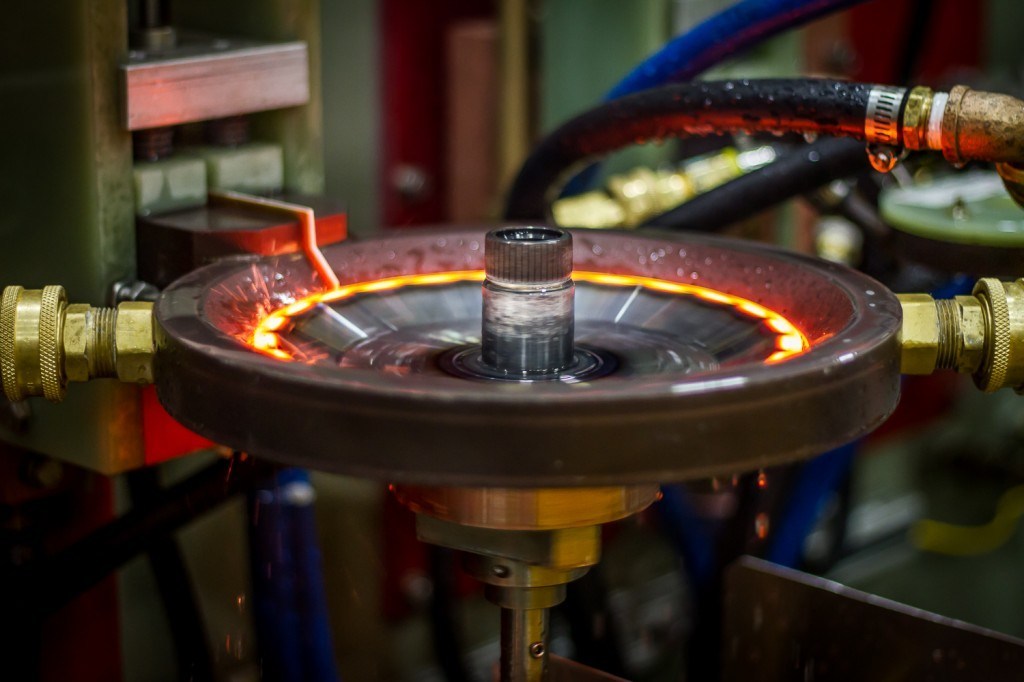

Heat Treat Systems (All Automotive Components)

Many metals require heating and/or heat treating to achieve their optimum physical properties. Inductoheat brand equipment leads the market in quality heating and heat treating with flexible and innovative systems that are designed and built for long-life performance. Inductotherm Group companies’ heat treating equipment gives you the most flexible heat treating solutions, engineered for today’shttps://www.inductothermgroup.com/products/heat-treat-systems-all-automotive-components/...

LEARN MORE »

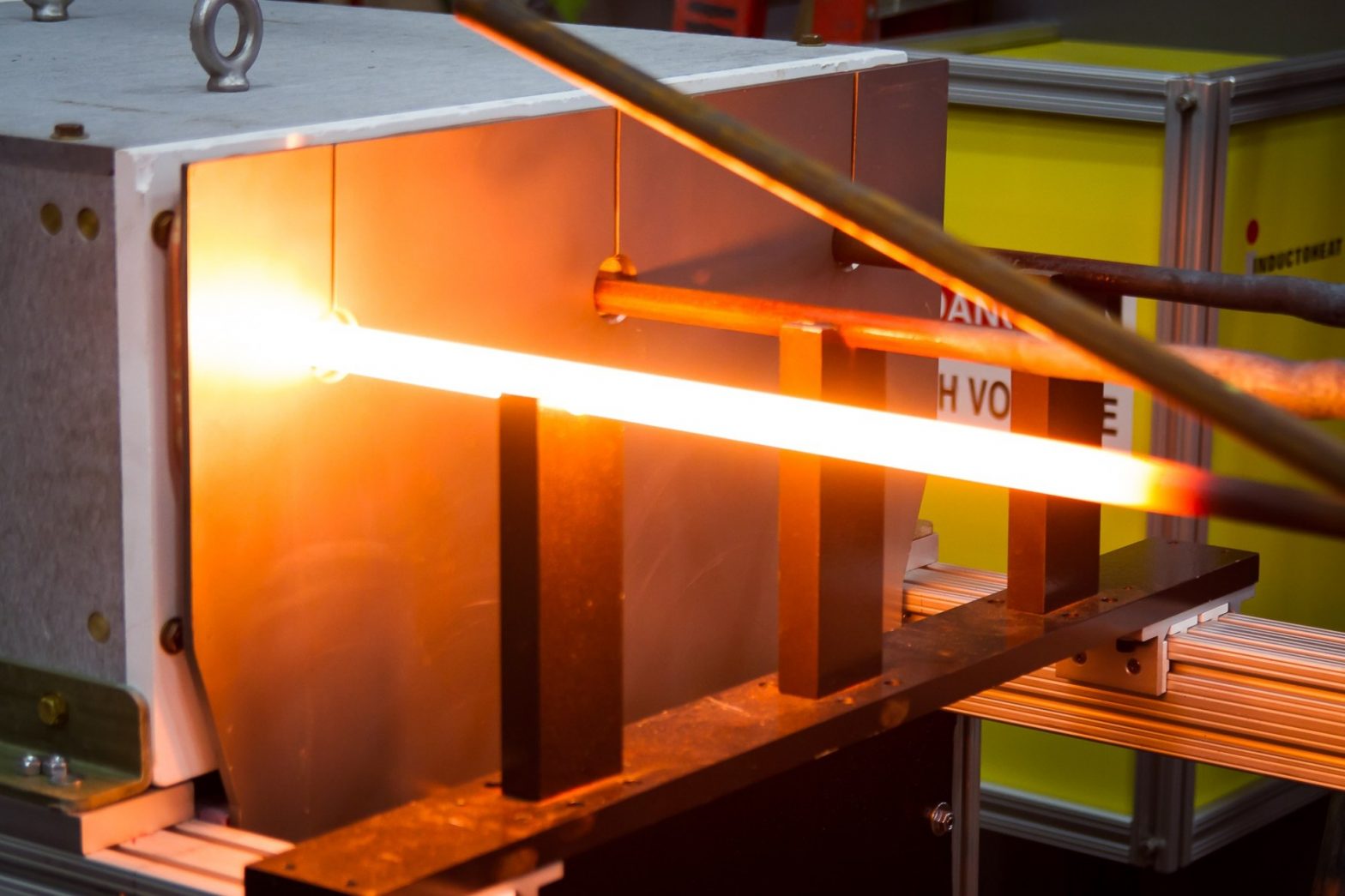

Induction Bar Heaters

Inductoheat® induction bar-end heating equipment is available for many sizes and shapes of parts. Multiple bar ends can be heated using differing types of induction coils. The powerful combination of advanced engineering, product innovation and over 55 years experience in induction heating has made Inductoheat® brand equipment the leader in billet and bar heating equipment....

LEARN MORE »

Induction Scanners

Inductotherm Group companies all over the world manufacture Inductoscan® brand induction scanning systems for scanning, rotary table heating and large part hardening. The modular heating systems’ unique design allows for a wide range of power supplies, controls and components to be integrated within a common base to better match current production needs. It can behttps://www.inductothermgroup.com/products/induction-scanners/...

LEARN MORE »

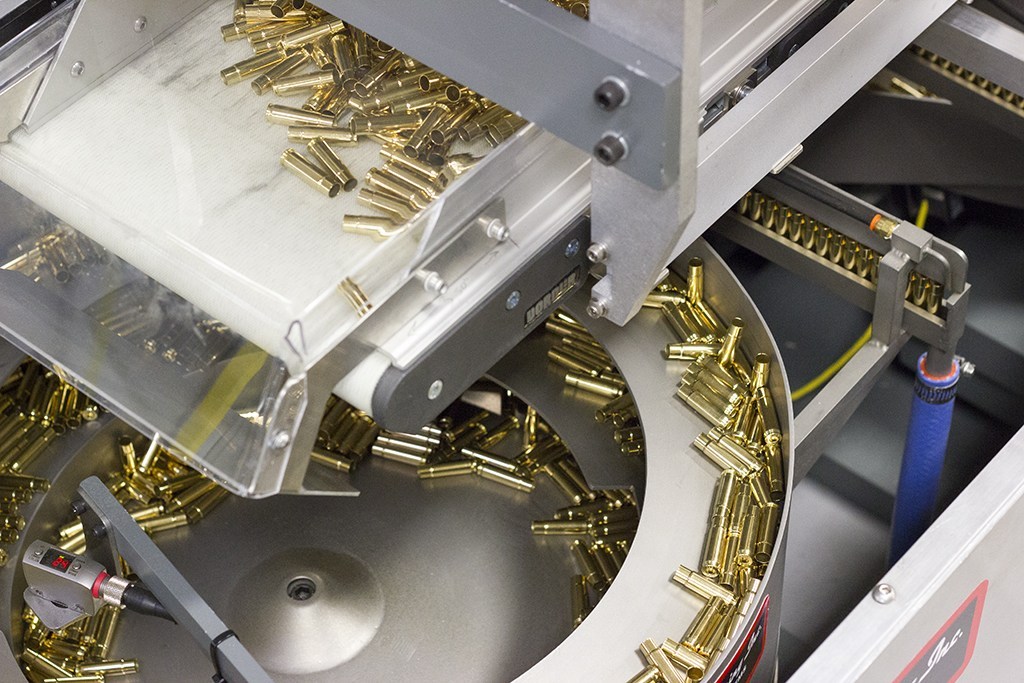

Munitions and Ammunition Annealing and Bonding Systems

Radyne brand ammunition annealing and bonding systems are used to make bullets for law enforcement and military applications, as well as for the hunting and shooting enthusiast. Radyne brand has a well-established history of designing induction heating equipment that is used for heat treating and forming shells to create specialized fragmentation patterns, penetrating characteristics, andhttps://www.inductothermgroup.com/products/munitions-and-ammunition-annealing-and-bonding-systems/...

LEARN MORE »