Industries

Locomotives and Rail Cars

While many focus on the slowing coal output as an indicator of serious trouble for railway transportation, the truth is that the industry is experiencing good (some say robust) financial health. A major consideration is the ability of railroad companies to improve their efficiencies, with many targeted to achieve operating ratios of 60% in the next few years.

Inductotherm Group customers around the world are commercially engaged with the rail industry in dozens of ways, not only with the production of metals that then require transport but also with the manufacture of thousands of tons of parts for both railway cars of every description and for railway infrastructure as well.

Select a Process

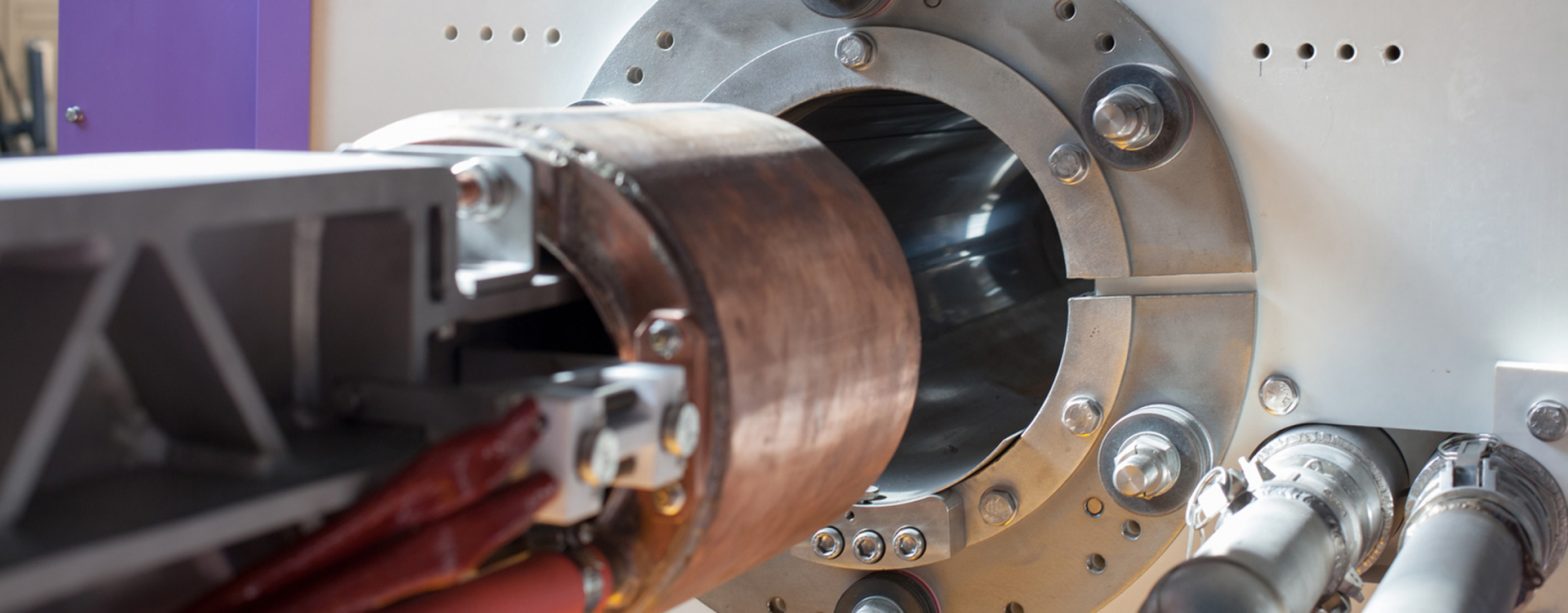

Boost Induction Heaters

The Banyard Boost Induction Heater has established itself as a low cost, highly compact, induction boost taper heater for use with either gas or induction pre-heaters. Using a servo-controlled billet positioning system to control both accuracy and speed, the Boost Induction Heater enables extruders to boost billet temperature and line speed, with a consequent increasehttps://www.inductothermgroup.com/products/boost-induction-heaters/...

LEARN MORE »

Horizontal Billet Heaters (nonferrous)

Inductotherm Group’s development of phase synchronized multi-zone power modules has made accurate static taper heating possible. A static taper heating coil is divided into a number of independently controlled zones, each with its own thermocouples executing its own power profile. This enables optimum temperature control. Synchronization of the modules ensures that there is a seamlesshttps://www.inductothermgroup.com/products/horizontal-billet-heaters-nonferrous/...

LEARN MORE »

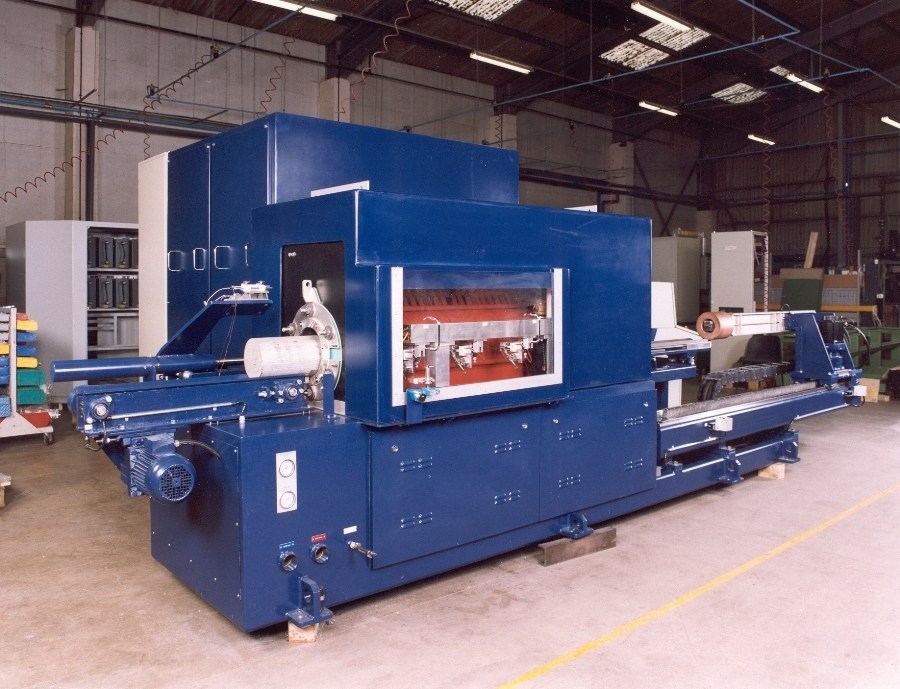

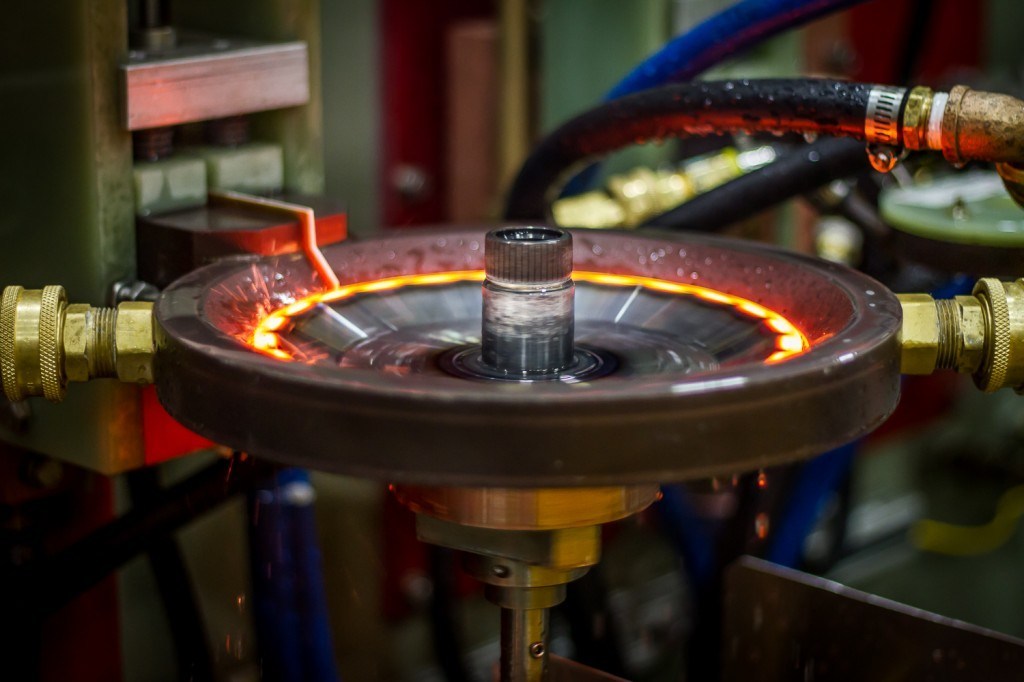

Rail and Mill Roll Hardening

Mill Roll Hardening Systems are becoming increasingly popular with the expanding development of cold mills which subject the rolls to high stresses. For the surface heating of steel parts, induction heating is considered to be the application best suited for this. Induction heating has many applications and is especially effective in hardening rolling mill rolls. Railhttps://www.inductothermgroup.com/products/rail-and-mill-roll-hardening/...

LEARN MORE »

Slab, Bloom and Transfer Bar Heaters

Our high-power density Slab, Bloom and Transfer Bar Heaters provide efficient and cost-effective technologies to bring surfaces to the optimal temperatures required for forming, rolling or forging. Metals which are susceptible to oxidation and scale formation such as titanium, if heated above certain temperatures, can be accurately heated using induction heating, thus increasing yield andhttps://www.inductothermgroup.com/products/slab-bloom-and-transfer-bar-heaters/...

LEARN MORE »

Zero Friction Billet Heaters

Banyard brand induction heating systems feature special mechanical handling technology designed specifically to address the needs of the aluminium micro-tubing sector. The Banyard solution enables aluminum billet transport with virtually zero friction. This is achieved by effectively minimizing the area of contact with the billet at all stages of the process. Smooth movement is alsohttps://www.inductothermgroup.com/products/zero-friction-billet-heaters/...

LEARN MORE »

Vacuum Aluminum Brazing Furnaces (VAB)

Vacuum Aluminium Brazing (VAB) is utilized to perform fluxless brazing of aluminum components in a high vacuum environment. The process demands tight control of temperature uniformity together with low vacuum leak rates and high repeatability. VAB will provide a component with very clean, high quality, high strength brazed joints. Consarc offers a wide range ofhttps://www.inductothermgroup.com/products/vacuum-aluminum-brazing-furnaces-vab/...

LEARN MORE »

Heat Treat Systems (All Automotive Components)

Many metals require heating and/or heat treating to achieve their optimum physical properties. Inductoheat brand equipment leads the market in quality heating and heat treating with flexible and innovative systems that are designed and built for long-life performance. Inductotherm Group companies’ heat treating equipment gives you the most flexible heat treating solutions, engineered for today’shttps://www.inductothermgroup.com/products/heat-treat-systems-all-automotive-components/...

LEARN MORE »

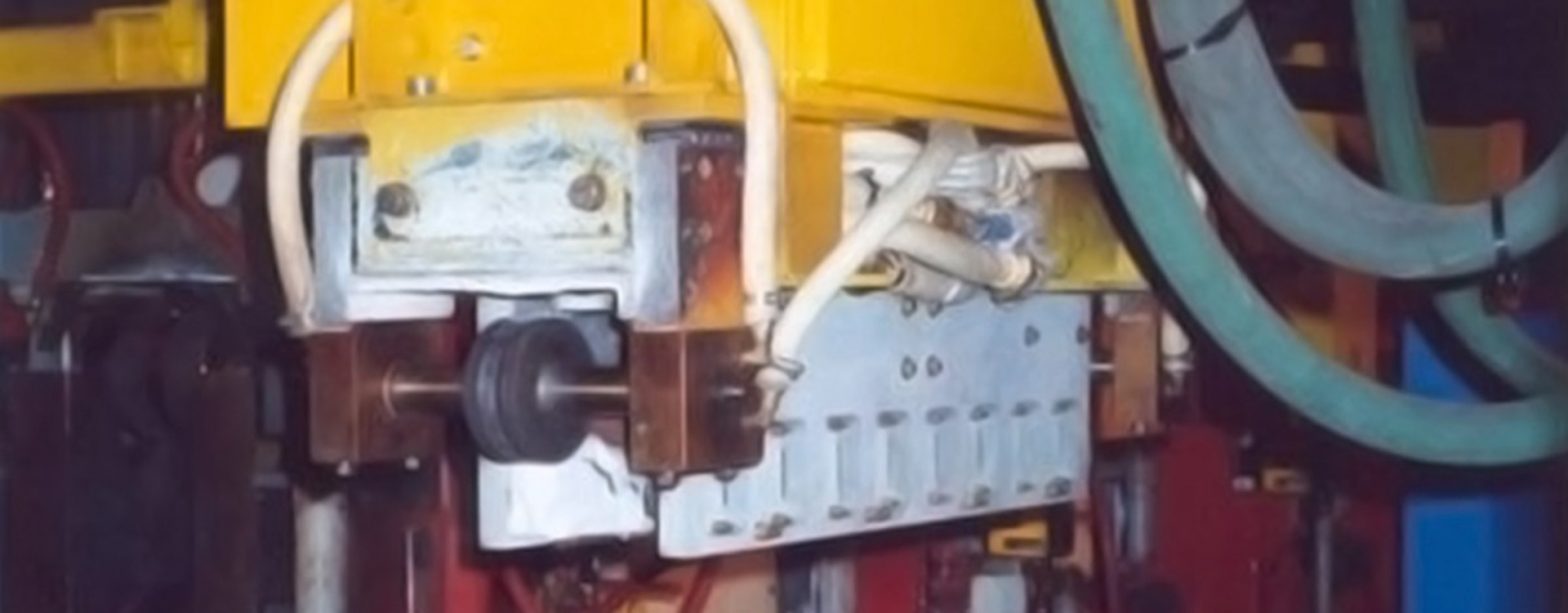

Induction Scanners

Inductotherm Group companies all over the world manufacture Inductoscan® brand induction scanning systems for scanning, rotary table heating and large part hardening. The modular heating systems’ unique design allows for a wide range of power supplies, controls and components to be integrated within a common base to better match current production needs. It can behttps://www.inductothermgroup.com/products/induction-scanners/...

LEARN MORE »

ARMS® (Automated Robotic Melt Shop Systems)

Inductotherm Group companies are the first to develop and manufacture an innovative automated robotic melt shop system, called the ARMS™ System. The ARMS System replaces the furnace operator on the open melt deck with a foundry robot that has integrated charging, slag removal, tool handling and remote viewing systems. This allows the furnace operator tohttps://www.inductothermgroup.com/products/arms-automated-robotic-melt-shop-systems/...

LEARN MORE »

Automated Pouring Systems

Inductotherm brand automated pouring systems for foundries and melt shops are designed for maximum productivity. They provide the higher levels of pouring accuracy required to eliminate quality robbing under-pours and metal wasting over-pours....

LEARN MORE »

Induction Holding Furnaces

Inductotherm Group companies manufacture two types of advanced holding systems: Channel furnaces and Mini-Heel™ furnaces. Both offer true volume flexibility for continuous and batch duplexing, and can maintain a continuous supply of metal ready to pour 24 hours a day, 7 days a week....

LEARN MORE »

Induction Melting Furnaces

Inductotherm brand coreless melting furnaces provide superior performance and outstanding durability for all your melt shop needs, regardless of the size of your foundry. Inductotherm Group companies offer a range of furnace sizes from small induction melting furnaces that meet the demanding requirements of investment casters, specialty foundries and the precious metals industry, to heavyhttps://www.inductothermgroup.com/products/induction-melting-furnaces/...

LEARN MORE »

Galvanizing Pots

As the world leader in induction melting technology, Inductotherm Group companies design and manufacture the industry’s most advanced systems for working with zinc and zinc alloys. We offer a full line of high performance galvanizing pots for coating applications, including specially-designed coating pots, pre-melting pots and emergency holding pots....

LEARN MORE »

Strip Heaters

Inductotherm brand equipment brings the world’s most advanced induction heating technology to continuous annealing and coating lines. Equipment includes in-line strip annealing systems, strip heaters, edge heaters, galvanneal heaters, boost heaters, tin reflow systems, paint dryers and anti-fingerprint systems. By adding induction technology to their process lines, customers can significantly reduce yield losses and increasehttps://www.inductothermgroup.com/products/strip-heaters/...

LEARN MORE »

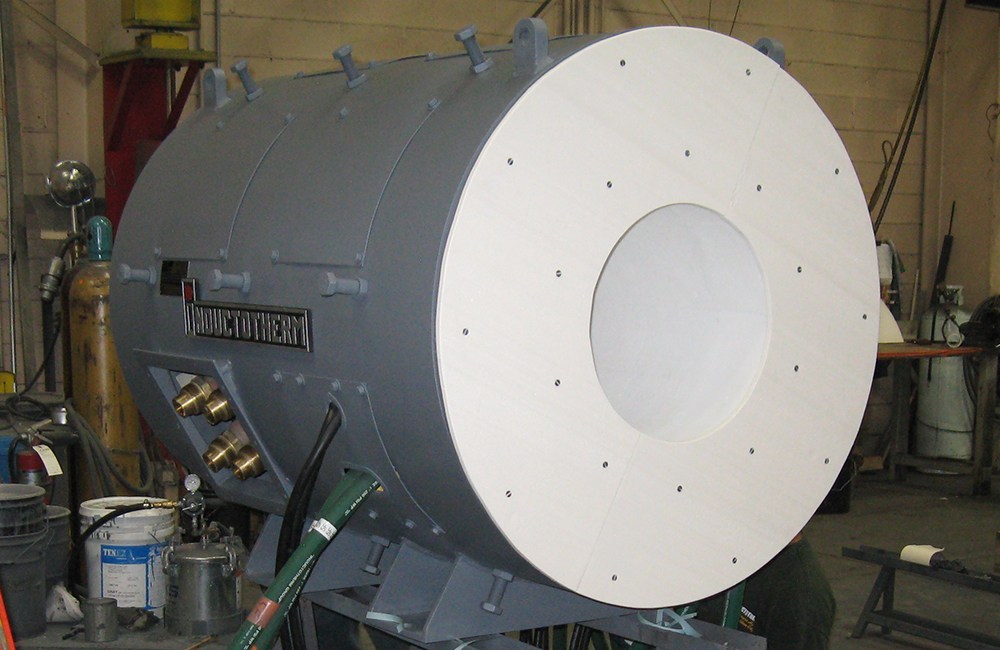

Vacuum Aluminum Brazing Furnaces (VAB)

Vacuum Aluminium Brazing (VAB) is utilized to perform fluxless brazing of aluminum components in a high vacuum environment. The process demands tight control of temperature uniformity together with low vacuum leak rates and high repeatability. VAB will provide a component with very clean, high quality, high strength brazed joints. Consarc offers a wide range ofhttps://www.inductothermgroup.com/products/vacuum-aluminum-brazing-furnaces-vab/...

LEARN MORE »

ElectroSlag Remelting Furnaces (ESR)

Consarc brand electroslag remelting furnaces improve the efficiency and performance of the process by combining the use of a “high fill ratio” electrode (an electrode whose diameter approaches that of the crucible) with an AC line frequency furnace design in which the main power conductors are arranged coaxially around the melt zone. The high fill ratio electrode provideshttps://www.inductothermgroup.com/products/electroslag-remelting-furnaces-esr/...

LEARN MORE »