Industries

Oil and Gas

The sheer size of the oil and gas industry is sometimes difficult to grasp. Total revenues globally exceed $2 trillion. Thirty billion barrels of oil are produced and distributed annually. Of the ten largest corporations in the world – ranked by revenues – three of them are oil and gas companies.

Not surprisingly, Inductotherm Group companies are heavily involved in the manufacture of thermal processing equipment and systems to support oil and gas operations around the world. One of our special capabilities involves OCTG—Oil Country Tubular Goods. Many Inductotherm Group companies around the world provide equipment for the manufacture of welded pipe and tubing. In an industry requiring superior quality welds to protect against leaks and environmental hazards across miles of underground pipes, Inductotherm Group has established an enviable reputation for its advanced technologies in OCTG welding operations.

Related Resources

Select a Process

Vertical Billet Heaters

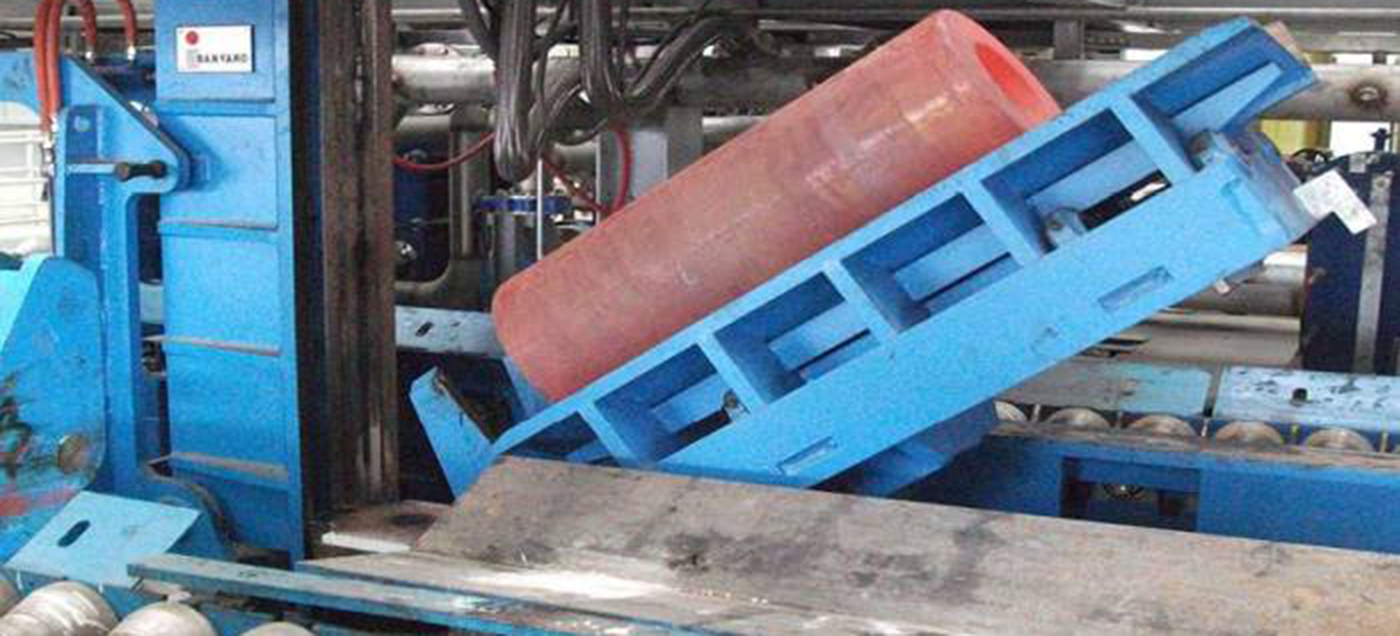

Banyard Vertical Steel Induction (VSI) systems have been designed for the precise vertical induction heating of solid or pierced billets and tubes. These systems heat billet diameters from 150mm to 460mm, and lengths from 300mm to 1500mm. Benefits include better temperature distribution, ability to vary the temperature profile along the billet length, and no billethttps://www.inductothermgroup.com/products/vertical-billet-heaters/...

LEARN MORE »

Vacuum Aluminum Brazing Furnaces (VAB)

Vacuum Aluminium Brazing (VAB) is utilized to perform fluxless brazing of aluminum components in a high vacuum environment. The process demands tight control of temperature uniformity together with low vacuum leak rates and high repeatability. VAB will provide a component with very clean, high quality, high strength brazed joints. Consarc offers a wide range ofhttps://www.inductothermgroup.com/products/vacuum-aluminum-brazing-furnaces-vab/...

LEARN MORE »

Induction Melting Furnaces

Inductotherm brand coreless melting furnaces provide superior performance and outstanding durability for all your melt shop needs, regardless of the size of your foundry. Inductotherm Group companies offer a range of furnace sizes from small induction melting furnaces that meet the demanding requirements of investment casters, specialty foundries and the precious metals industry, to heavyhttps://www.inductothermgroup.com/products/induction-melting-furnaces/...

LEARN MORE »

Flying Saws

Inductotherm Group companies offer a range of flying cold and friction saws to meet your tube and pipe cutting requirements. Alpha flying cold saws provide a near burr-free cut. Both single and multiple head designs are available for small or large product, or product which is reshaped into squares or rectangles. Blade surface speed ishttps://www.inductothermgroup.com/products/flying-saws/...

LEARN MORE »

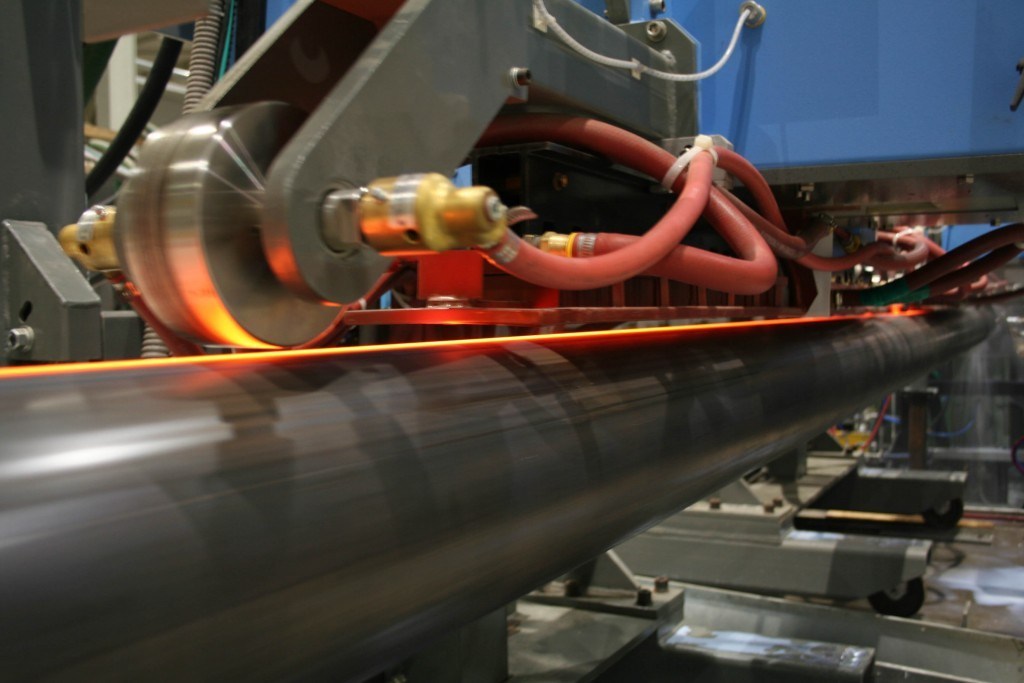

High Frequency (HF) Welders

Thermatool is the world’s leading brand in induction welding equipment. With two decades of success in solid state technology, and over fifty years of process knowledge, Thermatool solid state high frequency welders are the most advanced, reliable, field-proven welders available in the world today. Thermatool solid state welding units are designed to handle load fluctuations,https://www.inductothermgroup.com/products/high-frequency-hf-welders/...

LEARN MORE »

High Speed Flying Shears

Alpha® flying shears are the fastest, most efficient and accurate tube cutting systems available in the world today. Alpha flying shears provide a patented double-cut die set which enables producers to cut dimple-free, ready for market products directly off the mill. Inductotherm Group companies offers a full range of Alpha flying shears for nearly allhttps://www.inductothermgroup.com/products/high-speed-flying-shears/...

LEARN MORE »

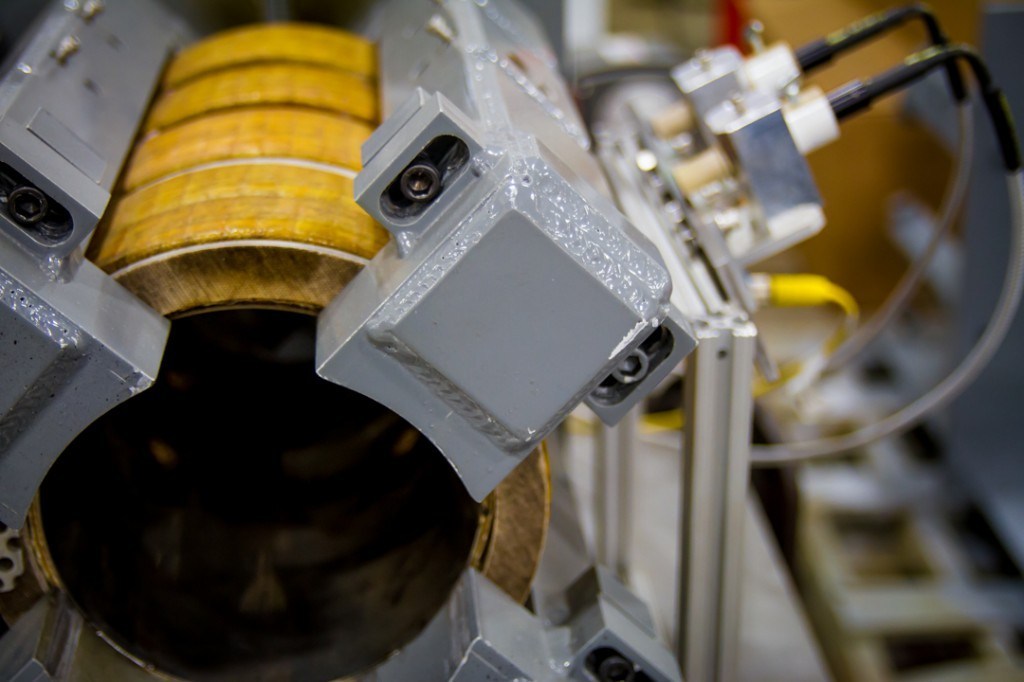

Induction Pipe Heaters with Flux Manager® Coil

iROSS™ Fluxmanager® Pipe-End Heating Units are designed for heating a variety of tubular products. These systems utilize patented Fluxmanager® induction heat treatment technology that yields superior temperature uniformity compared to conventional medium frequency designs....

LEARN MORE »

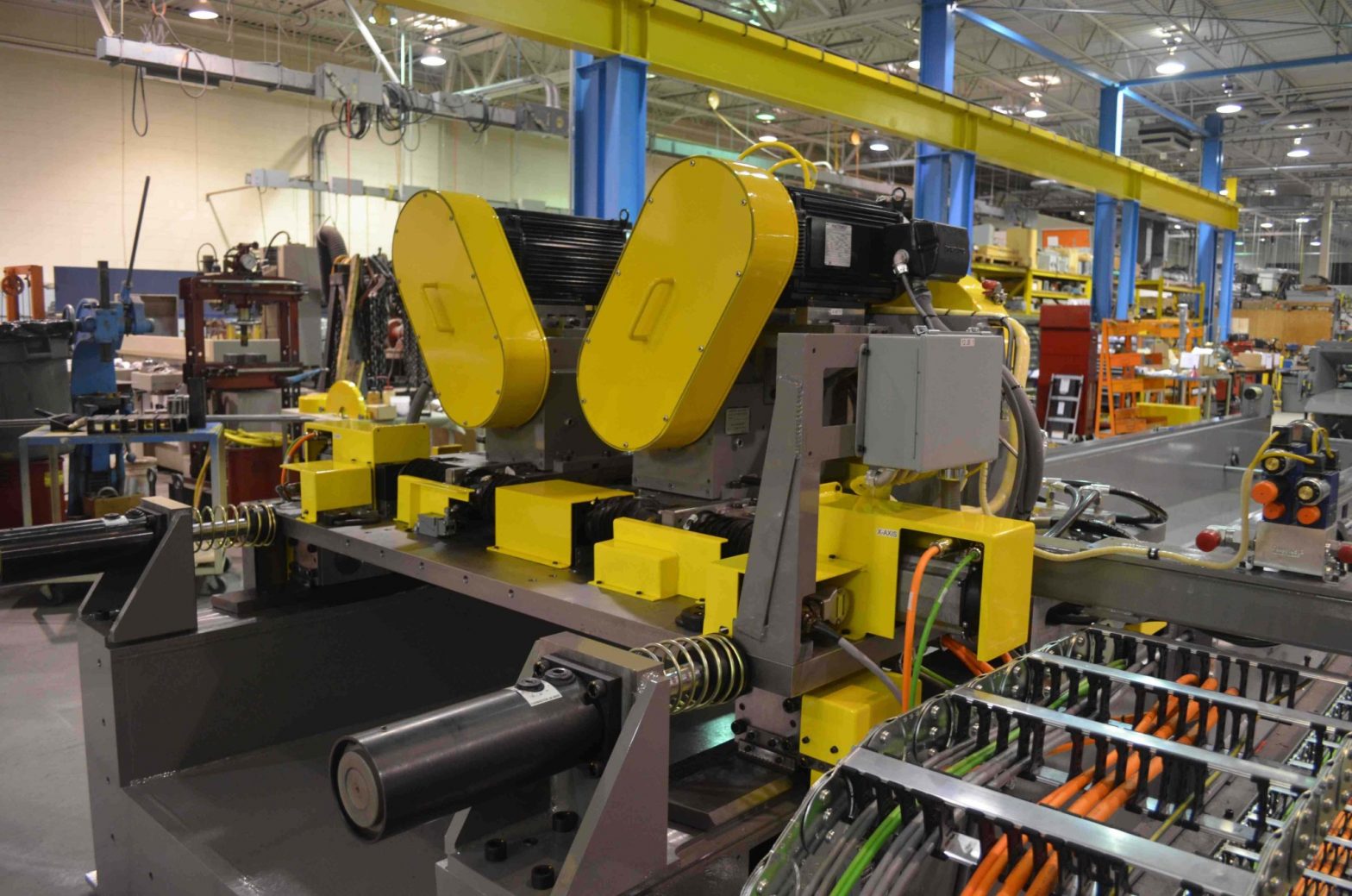

Quench and Temper Bar and Tube Equipment

Thermatool™ Quench and Temper lines can process 2, 5, 10, 15, 20 or 30 tons per hour for Austenitizing, Quench and Temper utilizing induction, gas, or electric furnaces coupled with the Thermatool™ Precision Quench™. Thermatool™ Quench and Temper lines feature Solid State Induction power supplies and a patented high-technology modular PrecisionSlot™ Quench. To be effective, these lines require the abilityhttps://www.inductothermgroup.com/products/quench-and-temper-bar-and-tube-equipment/...

LEARN MORE »

Tube Heaters/Seam Annealers

Many Inductotherm Group companies manufacture Thermatool brand seam annealing/normalizing systems for the tube and pipe industry. These highly efficient systems provide rigorous quality control and ensure process repeatability with their continuous temperature monitoring, required by all API pipe producers to prove that critical process temperatures have been reached during each shift. Powered by VIP™ Serieshttps://www.inductothermgroup.com/products/tube-heaters-seam-annealers/...

LEARN MORE »

ElectroSlag Remelting Furnaces (ESR)

Consarc brand electroslag remelting furnaces improve the efficiency and performance of the process by combining the use of a “high fill ratio” electrode (an electrode whose diameter approaches that of the crucible) with an AC line frequency furnace design in which the main power conductors are arranged coaxially around the melt zone. The high fill ratio electrode provideshttps://www.inductothermgroup.com/products/electroslag-remelting-furnaces-esr/...

LEARN MORE »

Vacuum Aluminum Brazing Furnaces (VAB)

Vacuum Aluminium Brazing (VAB) is utilized to perform fluxless brazing of aluminum components in a high vacuum environment. The process demands tight control of temperature uniformity together with low vacuum leak rates and high repeatability. VAB will provide a component with very clean, high quality, high strength brazed joints. Consarc offers a wide range ofhttps://www.inductothermgroup.com/products/vacuum-aluminum-brazing-furnaces-vab/...

LEARN MORE »

Vacuum Arc Remelting Furnaces (VAR)

VAR Furnaces are used for melting material that have already been melted and cast into electrodes that are near their full packing density. Consarc utilizes fully computerized controls to optimize reproducibility and ease of operation. Custom furnaces in laboratory scale or for the production of unusual geometric configurations are available upon request....

LEARN MORE »

Vacuum Induction Melting Furnaces (VIM)

Consarc brand equipment includes a variety of Vacuum Induction Melting (VIM) furnaces, including Electrode VIM systems, Master Alloy VIM systems, and small R&D systems. A wide variety of configurations are available to match customer requirements....

LEARN MORE »

Vacuum Precision Investment Casting (VPIC)

Consarc’s line of Vacuum Precision Investment Casting (VPIC) furnaces are uniquely designed to assure repeatable production with minimal maintenance and high furnace availability. Parts with an Equiax grain structure are easily produced in a Consarc VPIC system. With the addition of a mold heater and water-cooled chill plate, directionally solidified and single-crystal castings can behttps://www.inductothermgroup.com/products/vacuum-precision-investment-casting-vpic/...

LEARN MORE »