Article | White Paper | June 7th, 2019

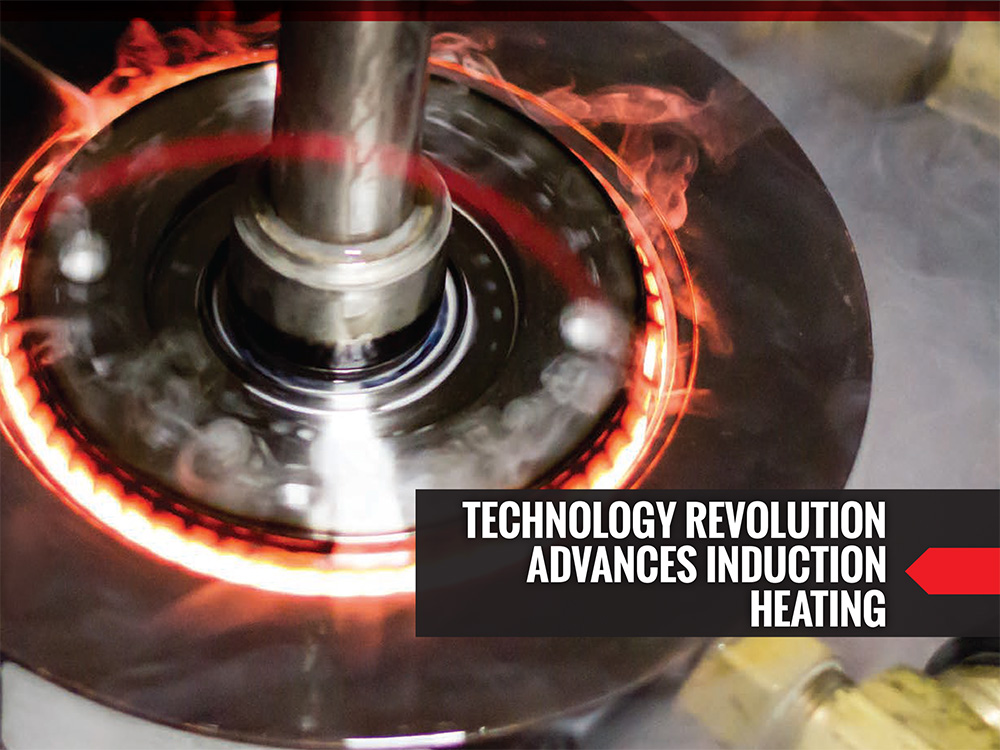

REVOLUTION—NOT EVOLUTION—NECESSARY TO ADVANCE INDUCTION HEAT TREATING

Modern, high quality equipment must be readily available and flexible enough to allow for easy retooling and reprogramming to process a variety of parts.

Gary Doyon,* Valery Rudnev, FASM,* Collin Russell,* and John Maher*

Inductoheat Inc., Madison Heights, Mich.

Factors traditionally used by commercial heat treaters to evaluate induction equipment include technical capability, quality, price, delivery, and longevity. However, in light of recent industrial trends, an even more important factor is flexibility[1-3]. In the past, parts suppliers would often have a particular part contract for many years. Today, contracts can move from supplier to supplier much more frequently, so winning a contract over the competition could require a supplier to assess new induction equipment that can perform the job, purchase and setup the equipment, and complete a production part approval process (PPAP) to be in production in a short period of time. Modern, high quality, and reliable equipment must be readily available and must allow easy retooling and reprogramming to process different parts.