Article | White Paper | June 7th, 2019

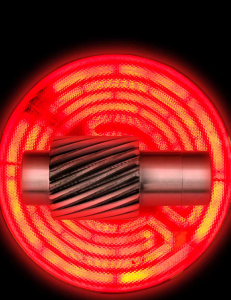

Computer Modeling Helps Prevent Failures of Heat Treated Components

Consider this scenario. Following the development stage, an induction hardening machine is built, completes a successful run-out, and is shipped to the customer. After a number of successful production runs, parts begin to experience cracking during the hardening operation. A check of induction machine process parameters (power, frequency, quenchant temperature, concentration, pressure and flow, part positioning inside induction coil, etc.) shows everything is in order. The question is why does cracking in parts suddenly occur? Such an occurrence could present a challenge in determining the root cause of cracking and ways to eliminate it. Cracking that occurs during induction hardening often ex-poses failures that occurred during earlier processing stages, including, but not limited to, the quality of steel, and imperfections in the material caused by casting, rolling, forging, machining, etc.