Article | June 7th, 2019

Subtleties of induction heating of aluminum, magnesium and copper alloys

By Dr. Valery Rudnev

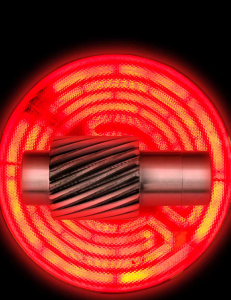

Steel components by far represent the majority of hot worked and heat-treated parts for which electromagnetic induction is used as a source of heat generation. At the same time, aluminum, magnesium, titanium, copper as well as many other non-ferrous metals and alloys are also inductively heated for a number of commercial applications producing various properties and microstructures (Fig.1).

Popularity of using non-ferrous metallic alloys has been dramatically increased in the last decade chiefly due to an implementation of light-weight initiatives by automotive industry to meet more stringent federal Corporate Average Fuel Economy regulations. Similar changes are occurring in aerospace and other industries. Practically every metallic part is in process of being revised to optimize engineering properties including weight-to-strength ratio, resistance to specific corrosion media, yet satisfying stringent

safety requirements and maximizing process effectiveness. Enhanced thermal and electrical conductivities, thermal stability and appropriate grain structures are other properties that can be also critical in certain applications.